Common Mistakes In Rocker Switch Wiring And How To Avoid Them

The process of working with electrical elements can be very frustrating, particularly when wiring a simple rocker switch.

You may spend hours trying to make it right, only to find out the switch isn’t working. There are cases where the switch was not the problem, but the connection to the switch was.

Misunderstanding of terminals, incorrect wire type, or incorrect voltage may result in malfunctions, short circuits, or even safety issues. These problems may seem overwhelming, especially when it’s your first time doing them.

Understanding the main pitfalls and how to prevent them will help you make wiring easier, safer, and more reliable.

This article discusses six common errors in rocker switch wiring and how to prevent them.

1. Choosing Incorrect Switch

The main error most individuals make is choosing a switch that does not meet the circuit’s requirements. Each circuit has its own voltage and current ratings, and using an unsuitable switch can lead to overheating or failure.

For example, in rocker-switch wiring, you must understand which type of switch you require: SPST, SPDT, DPST, or DPDT. Both types do not treat electricity in the same way. Hence, you need to examine the switch’s rating before purchasing and ensure it fits your device.

By doing so, you avoid wasting time and make the switch work safely and effectively.

2. Misidentifying Terminals

The other widespread problem is confusion over switch terminals.

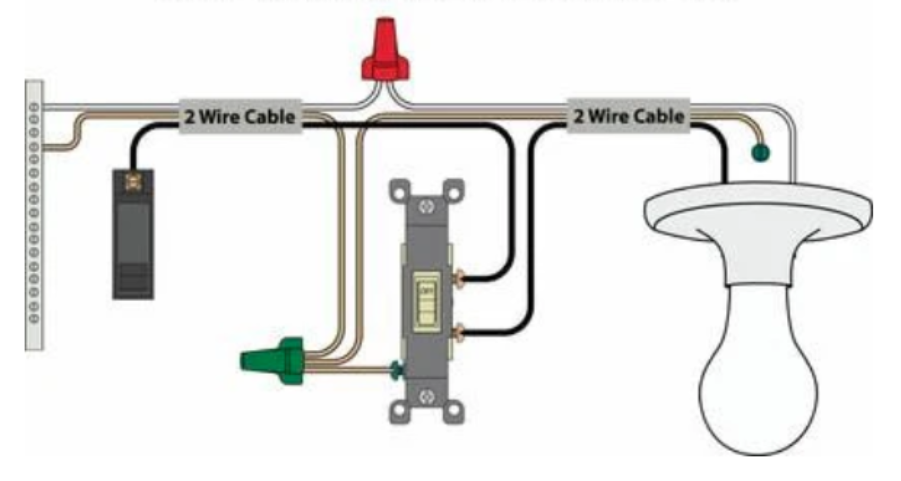

Rocker switches are often designed with three terminals: power, accessory, and ground. Connecting wires to the wrong terminals could damage the device or even break the switch.

To prevent this, use the wiring diagram that comes with the switch. Besides, label the terminals (where necessary). Good identification ensures each wire reaches the correct destination, enhancing safety and functionality.

3. Ignoring Circuit Type

The first thing many beginners forget to consider is whether the circuit is DC or AC, which can cause compatibility issues. Rocker switches are designed to operate on alternating current (AC) and direct current (DC).

Application of an AC-rated switch to a DC circuit, such as an AC-rated switch, may result in overheating or a short-circuit. The type of circuit should always be checked, and a switch of that type selected.

This is a simple measure that helps avoid additional stress and accidents and extends the life of both the switch and the object to which it is connected.

4. Using Incorrect Wire Gauge

The wire gauge for safe rocker-switch wiring is critical. The wires should not be too thin, as this can lead to overheating, and the cables should not be too thick, as the wires might not slide into place easily.

Before commencing, calculate the current your circuit will carry, then choose the correct wire gauge. Excessive insulation removal or uncovered wiring can also result in short circuits.

Thus, the proper choice of wire size and its careful preparation will make the connection safe and ensure performance with minimal risk.

5. Not Securing Connections Properly

It does not matter how right the switch and wire you have selected are; intermittent failures may result from poor soldering or loose connections.

Unsoldered wires may disconnect either by vibration or heat. Likewise, terminals that are not firmly clamped can cause resistance, leading to heat accumulation. The soldering should be done correctly, and the connections must be checked.

Besides, do not over-tighten screws, as that may damage the terminals. A secure connection ensures high reliability over time and will avoid failures.

6. Skipping Test Run

The last mistake is installing the device without even testing the switch. With testing, you can verify that everything is working, i.e., that the switch operates as designed and that all your wires are connected correctly.

Verify the functionality with a multimeter or a simple test, if possible, before encasing everything.

It could save time, reduce rework, and reduce the risk of electrical hazards. Pre-testing before assembly means that everything functions safely and correctly from the beginning.

This extra step gives you confidence that the installation is reliable and avoids surprises once the device is fully assembled.

Conclusion

Rocker switch wiring can be a pain if you don’t pay attention to what you are doing and how you wire things. The whole thing is not that difficult; however, providing simple pointers on how to do this adds a lot of frustration down the road, without, like anything else in life, an appropriate direction to make life a little easier.

Select the correct switch, correctly identify connections, take circuit type into account when computing wire gauge, and you are on your way to a successful installation. You can avoid frequent errors while keeping your wiring project safe, efficient, and reliable by using these tips.

If you know what to watch out for, a seemingly hard job becomes an easy, repeatable process.