The Benefits of Homogenizer Packages for Food and Beverage Processing

Within the dynamic realm of food and beverage production, the finely tuned process of homogenization plays an indispensable role. This essential technique ensures consistent quality and flavor profiles across various consumables, ranging from dairy products to beverages. Homogenizer packages are designed to address specific industry needs, offering custom solutions that enhance the manufacturing process. Understanding the advantages they bring allows businesses to make informed investments in their production capabilities. Keep reading to uncover the significant benefits of incorporating homogenization technology into food and beverage processing protocols.

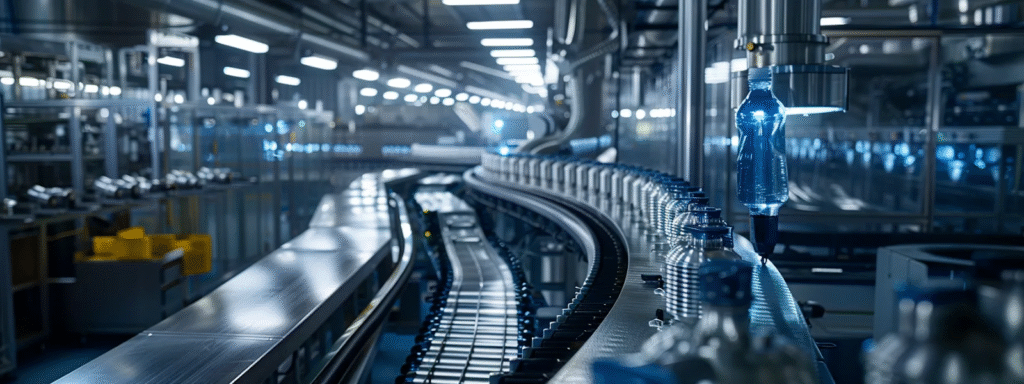

Understanding Homogenizer Packages and Their Role in Food Processing

Homogenizer packages are comprehensive systems that integrate different functionalities to streamline the food manufacturing process. They consist of a host of equipment coordinated to break down particles, resulting in a uniform product. The role of these packages in food processing cannot be overstated, as they prevent separation and improve the textural consistency of consumables.

These systems are especially advantageous when processing materials that have a tendency to separate over time, such as milk or creams. By reducing particle sizes, homogenization effectively distributes elements evenly throughout the product, enhancing both stability and appearance. The result is a visually appealing and palpably smoother product that appeals to consumer senses.

Moreover, homogenizer packages are engineered to cater to varying production scales. The flexibility in design allows for both small-scale artisans and large industrial operations to benefit from their application. It is this scalability that makes homogenizer packages for processing not only functional but also economically viable for all sizes of food and beverage enterprises.

Extending Shelf Life and Stability of Food Products Through Homogenization

Homogenization is instrumental in extending the shelf life and stability of perishable food products. The process itself reduces the likelihood of microbial growth by creating unfavorable conditions for bacteria and other pathogens. This extension of shelf life is essential for reducing waste and maintaining product integrity during transportation and storage.

Through uniform particle distribution, homogenization also contributes to the stabilization of food products. This means that foods are less prone to separation or degradation over time, safeguarding nutritional value and taste. Longevity on the shelf directly translates to reduced costs for manufacturers, as products endure longer without quality degradation.

Furthermore, stable food products require fewer preservatives, which benefits health-conscious consumers who prefer natural ingredients. As such, the appeal of products that offer these qualities can open up new markets and customer bases, providing businesses with a competitive edge.

Streamlining Production Efficiency With Integrated Homogenizer Systems

Production efficiency is at the heart of profitable operations, and integrated homogenizer systems play a vital part in achieving this goal. By incorporating these systems into production lines, manufacturers benefit from significantly reduced processing times. The streamlined workflow further bolsters productivity, allowing for more goods to be produced with less downtime.

Additionally, the automation capabilities associated with modern homogenizer packages allow for consistent results with minimal human intervention. This reduction in manual labor not only cuts costs but also diminishes the likelihood of human error, thus ensuring a more reliable output. Moreover, automated systems provide better monitoring and control, optimizing the homogenization process to suit specific product requirements.

Enhanced sanitation is another critical advantage offered by these systems. Easy clean-in-place (CIP) configurations mean that the equipment can be sanitized without disassembly, maintaining high levels of hygiene while reducing labor and downtime associated with cleaning. This aspect is particularly important in an industry where contamination can have severe consequences.

Meeting Regulatory Standards and Improving Food Safety With Homogenization Technology

In today’s market, regulatory compliance and food safety are top priorities for any food and beverage manufacturer. Homogenization technology supports these aims by ensuring products meet the stringent standards set by health authorities. The process reliably produces safe and standardized items that consumers can trust, which is paramount in maintaining brand credibility.

By reducing the particle size and evenly distributing components within a product, homogenization makes it easier to achieve uniform thermal treatment during pasteurization. This uniformity ensures that all parts of the product reach the necessary temperatures to eliminate pathogens, resulting in a safer end product.

The ability to maintain rigorous quality control throughout production is another advantage afforded by these systems. Real-time data collection and monitoring enable producers to quickly address any deviations in the process, thereby averting potential food safety issues before they reach the consumer.

Altogether, the integration of homogenizer packages within the food and beverage industry heralds numerous benefits, from enhanced product quality to improved safety and efficiency. Overall, these systems are indispensable tools that help producers meet the challenges of a demanding and ever-changing market landscape.